Sharing of Typical Cases

| IP Rating Test (Sealing Product Test)It is very difficult to ensure the reliable sealing due to the small parts dimensions, thin panel wall, many structures with right angle and arc surfaces in wearable electronic devices. At the same time, while performing the gas tightness test on a product without air inflation inlet, such as finished product of smart watch, there is need to use the same set of tools to successively detect minor and major product leakages. Once deviation occurs in the design, it is very likely that neither major nor minor leakages are detected in products in which leakage actually exists. Thus, specialized R &D and design is of particularly importance in such kind of leak detection work. As a professional leak testers manufacturer, we have been working closely with customers such as Huawei, BYD, Foxconn, Flextronics, Gore, and Xiaomi for many years. Our differential pressure leak detectors are widely used in IP rating tests of smart phones, tablet PCs, smart watches, bracelets, fingerprint sensors, cameras, SPEAKER and other products. The waterproof test with diving depth of 300m can be realized. |

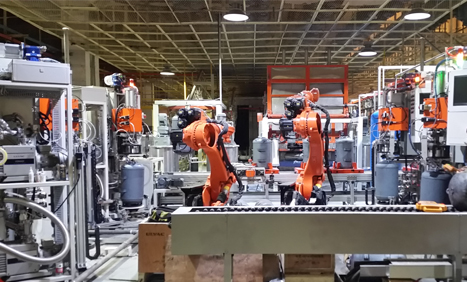

| Engine Leak DetectionIn the event of leakage in an automobile engine and its components, accidents as minor as breakdown of vehicle and as major as fire or explosion may be caused. Therefore, all automobile manufacturers attach great importance to airtight leak detection equipment, and provide almost harsh requirements for the reasonableness of sealing structure of leak detection equipment, reliability of seal, stability of leak detection data, automation degree of leak detection equipment, and other indicators. As a professional leak detection manufacturer, we have been working closely with famous brands at home and abroad such as Toyota, Honda, Ford, Mazda, Volkswagen, FAW, Chang'an, Great Wall, Dongan, New Wei San, Mahle, Keihin and so on for many years. Our flow type leak detector, differential pressure leak detector, nitrogen & hydrogen leak detector and other products are widely used in the leak detection of cylinder block, cylinder cover, cylinder head casing, oil sump, water pump, oil pump, intake and exhaust manifold, turbine housing and other engine parts. Good results are obtained, while trusts and praises from customers are received. |

| Leak Detection of Electric Water Heater LinerNormally, the inside tank capacity of electric water heater line is as small as several tens of liters and as large as several hundred liters. Besides that, the number of welded joints is larger and the weld seam is longer. In this case, if it is desired to accurately detect the leak points of each weld bead, while ensuring the detection efficiency and costs, nitrogen & hydrogen leak detector seems to be the only choice for two reasons, i.e. on one hand, the tracer gas (nitrogen-hydrogen mixture) has low cost, and on the other hand, the multi-channel nitrogen & hydrogen leak detection system can not only detect leakages but also locate leak points. The world's first fully automatic hydrogen & nitrogen detection system for electric water heater liner developed by us for Haier successfully passed the acceptance check and put into production in 2017. It successfully solved the difficult detection problem of large volume and small leak rate in the industry. |